Generation 4 - What's new

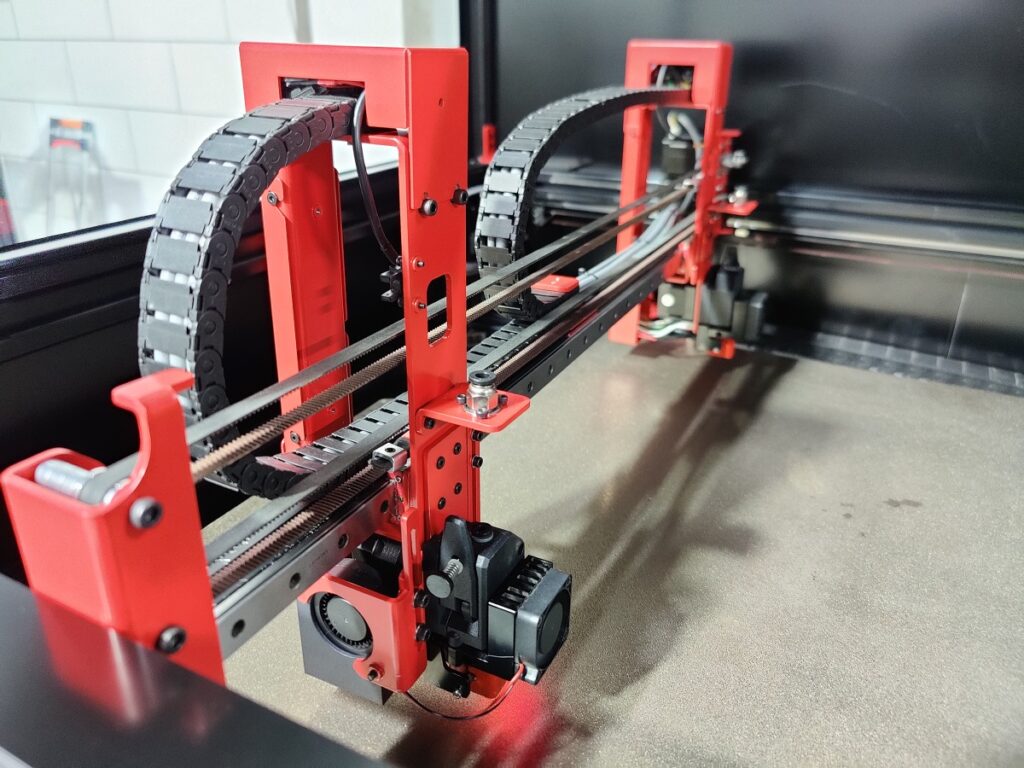

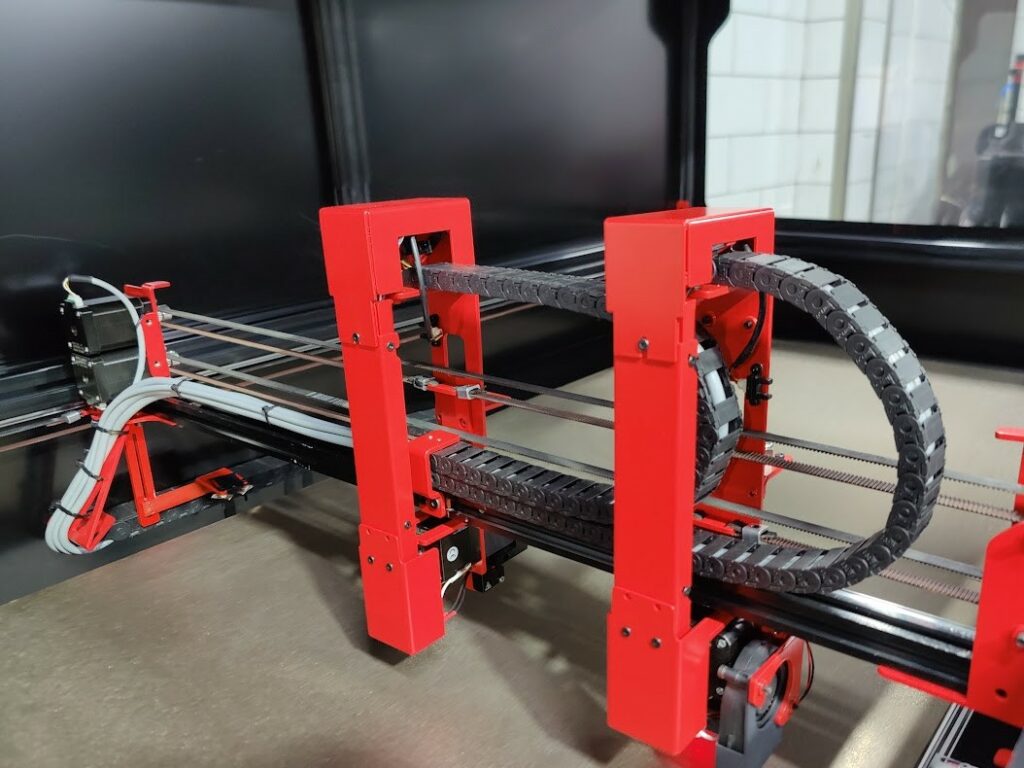

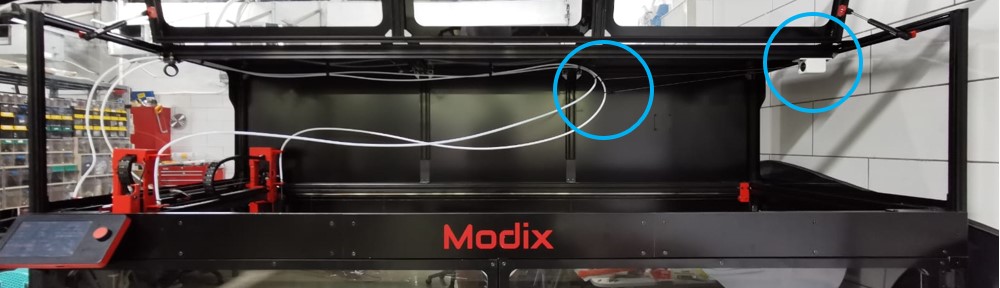

IDEX dual printing add-on

“IDEX” stands for independent dual extruder, where each extruder is independently controlled. Meaning, while the active extruder is printing, the second extruder is “parked” outside the printing area. Therefore, printing advanced models with

internal geometries is made possible more easily, by using water-soluble filament.

The IDEX is sold as an add-on in all generation 4 printers.

It includes:

- Secondary printing subsystem: Griffin print head, clog detector, PTFE, spool mount.

- Motion system: secondary Y axis motor with the required components (belts, pulleys etc.).

- Metal brackets for both Y axis and print heads

- Wires, drag chains and optical end-stops.

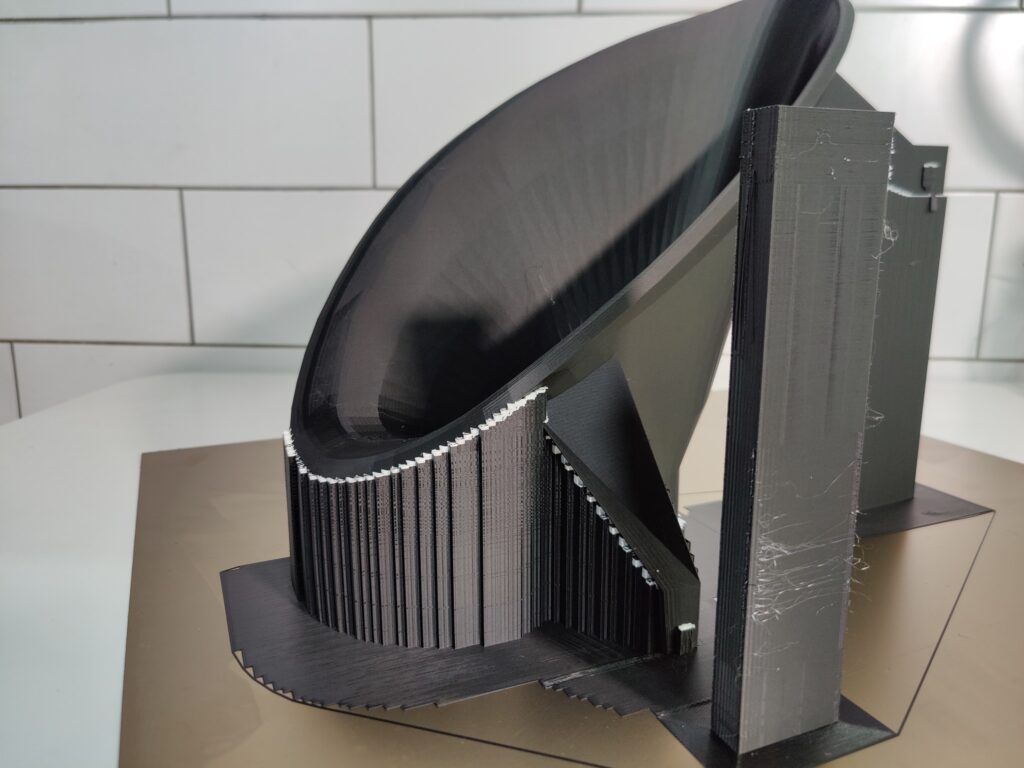

Breakaway Support Filament

Printing the dense support layer only with a breakaway support filament, saves a lot of manual labor for support removal. Since there is no need to keep an air gap between the dense support and the model itself, the supported surface comes out clean and smooth.

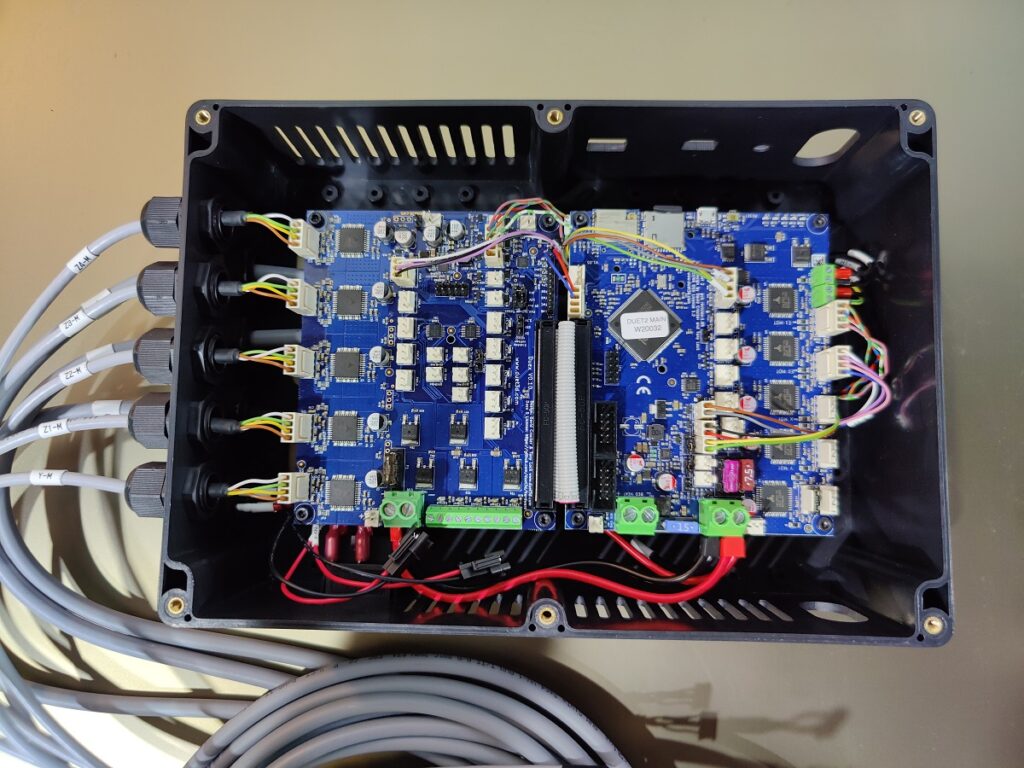

Fully automated calibration

With Generation 4, all our line of 3D printers now come with the electronic expansion board named “Duex 5” (before, this was provided by default only with BIG-Meter and BIG-180X models).

By using Duex 5, a dedicated stepper motor driver is allocated for each Z and X axis motor. As a result, Modix printers now offer a full set of automated calibration routines to all Generation 4 models, including automated bed tilt, bed leveling, gantry alignment and Z offset calibration.

Fast 3D Printing

Modix’s Generation 4 printers are capable of printing significantly much faster than before. Travel speed of up to 350 mm/s, and printing of up to 250 mm/s.

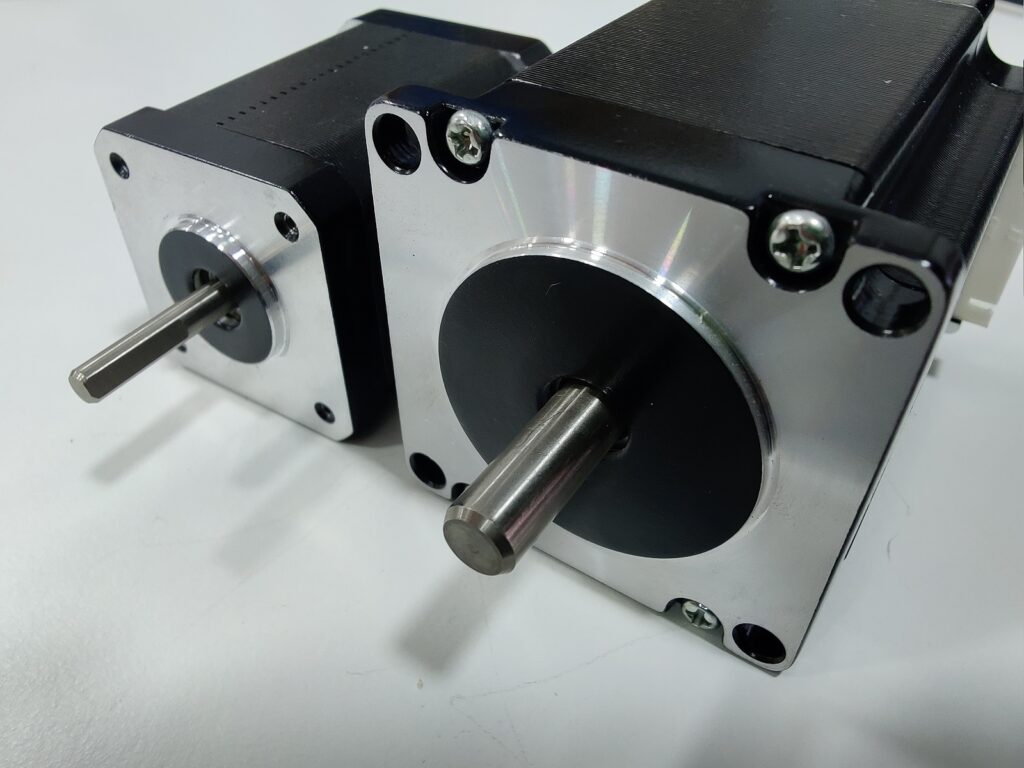

This higher print speed has been made possible thanks to strong NEMA 23 motors on the X axis instead of NEMA-17 motors. In addition, the weight has been reduced on the Y axis as the weight of one motor is split now into two independent ones, using the IDEX setup.

Emergency stop button

Modix Generation 4 models are all equipped with an emergency stop button. The stop button resets the Duet controller and stops printing immediately.

Frontal power switch, tilt screen & emergency button

The taller printers, BIG-Meter and BiG-120Z now have some add-ons by default:

- Tilt screen – Mounted on articulated arm, the tilting touch screen provides easier access to information and commands for customers at different heights. It is also very convenient to use during system calibration: you can rotate the touch screen for easy access when you are working and looking at the print head performance.

- Frontal secondary power switch – this feature is very convenient if the printer is located in a tight corner, or in between other equipment.

- Large secondary reset button – improves accessibility to the reset button.

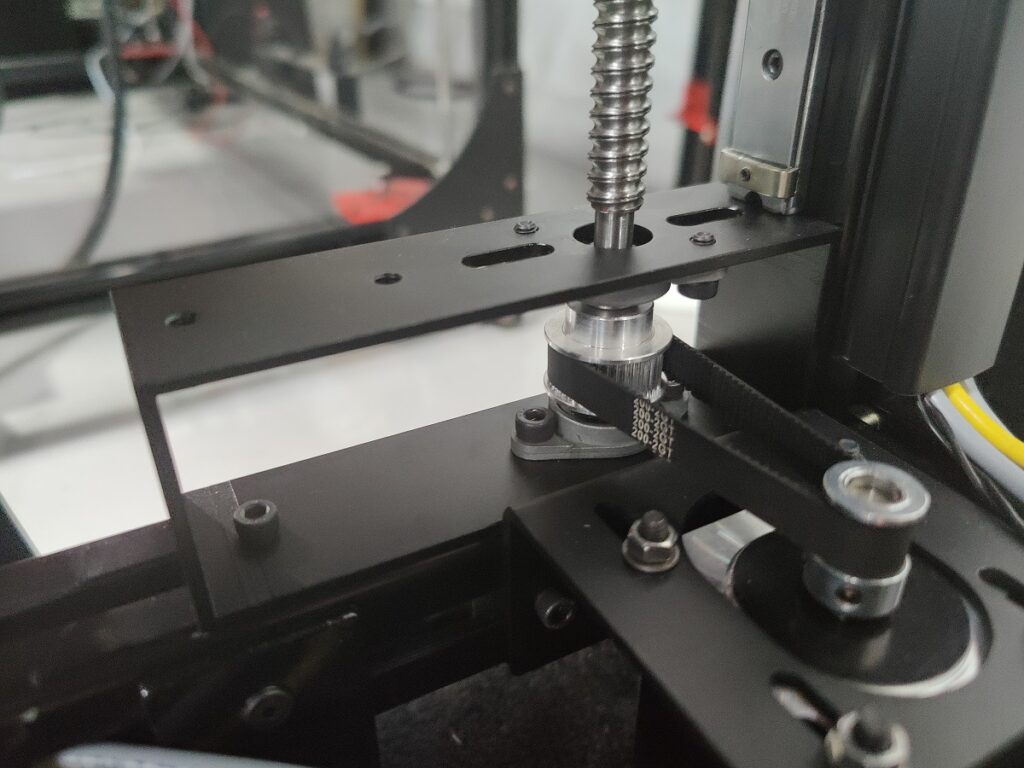

Improved Z axis

Modix Generation 4 3D printers have stronger Nema-23 motors and CNC machined brackets that hold the bed firmly and at a higher level of accuracy.

* The photo on the right shows the Z bottom CNC parts for the taller printers: BIG-Meter and BIG-120Z.

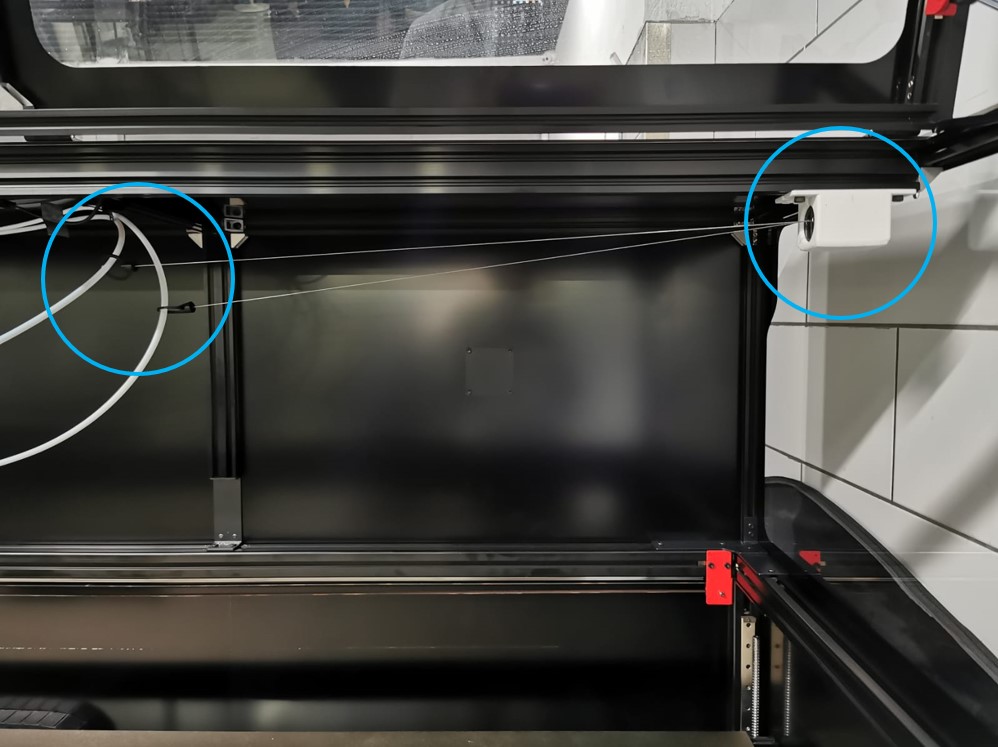

Optical end-stops

End-stop switches are now upgraded to optical switches in all Generation 4 printers. Optical switches are more accurate and have a high level of repeatability over time. This is especially important for job recovery after a power outage.

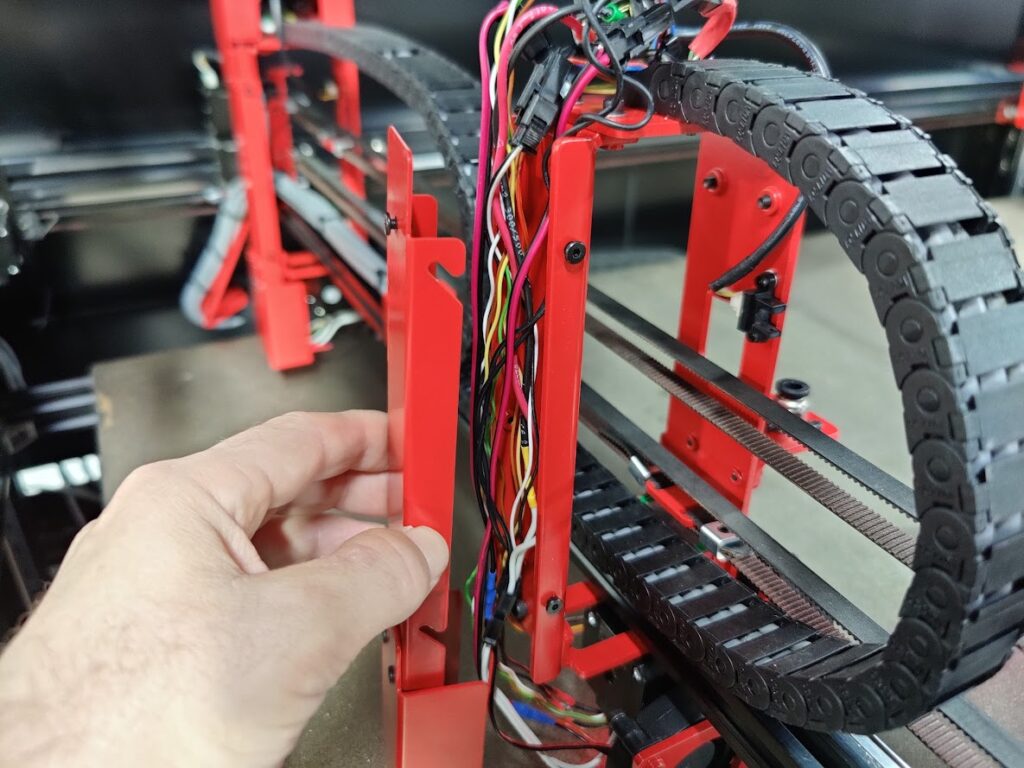

Wire Management

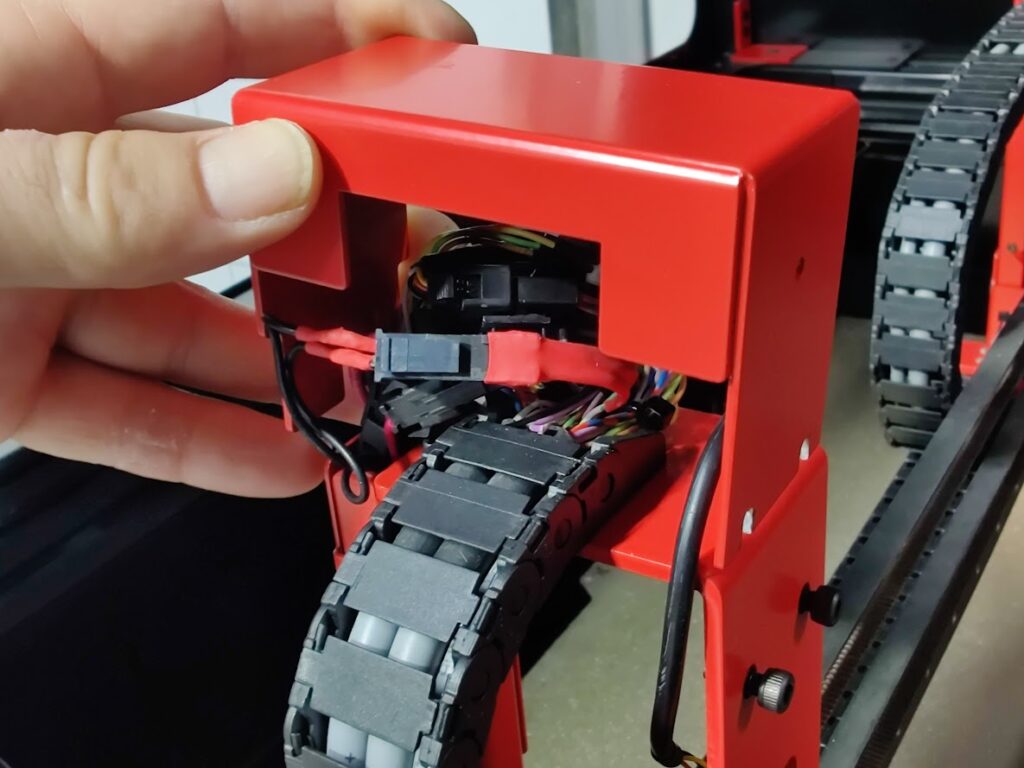

With generation 4, all the wire connectors are located on top of the print head. Both top and back covers are easily slide-in – & slide-out for maintenance. No need to remove the mounting screws.

Back cover on

Back cover slide-out

Top cover on

Top cover slide-out

PTFE retractable reel

With Generation 4, the PTFE tube rests in a roller guide that ensures its most relaxed position, and as a result, this reduces the friction inside the tube.

Learn more about Modix's technology

Check Tech-specs page for additional in-depth technical specifications.

Including information about the Griffin print head, calibration methods, important add-ons such as the air filter and more.