MAMA-XL3000

Modix MAMA XL3000 –

The Next Frontier in Large-Scale 3D Printing

The Modix MAMA XL3000 is the latest innovation in large-format 3D printing, designed to meet the growing demand for massive, high-precision parts. With a generous print volume of 3,000 x 1,000 x 1,000 mm, this advanced machine is perfect for industries requiring large, complex parts with minimal post-processing.

Versatile Configurations for Maximum Flexibility

Starting as a filament-only printer, the MAMA XL3000 is designed with future flexibility in mind. Soon, it will be available in a dual configuration, allowing users to switch between filament and pellet extrusion. This dual-material capability opens up a range of possibilities, providing both the precision of filament printing and the cost-efficiency of pellet extrusion for high-volume applications.

Superior Motion Control with Static Bed Design

The key differentiator of the MAMA XL3000 is its static bed design. Unlike the MAMA 1700, where the print bed moves along the Z-axis, the XL3000’s print bed remains stationary, while the extruder head moves along all three axes (X, Y, and Z). This design ensures superior stability, leading to improved print quality, especially for tall and intricate models, while also simplifying maintenance and calibration.

Precision Engineering for Professional Applications

With industrial-grade components, advanced motion systems, and superior heat management, the MAMA XL3000 is engineered for professional applications, including automotive prototyping, aerospace, architecture, and large-scale product design. Whether you need to create prototypes or functional parts, the MAMA XL3000 ensures reliable, repeatable results with excellent layer adhesion and minimal distortion, even at its largest scale.

Ready for the Future of Additive Manufacturing

The Modix MAMA XL3000 brings a new level of flexibility and scalability to large-format 3D printing. With its future-ready dual material system and enhanced bed stability, it empowers businesses to innovate faster, reduce costs, and take on projects that were previously out of reach.

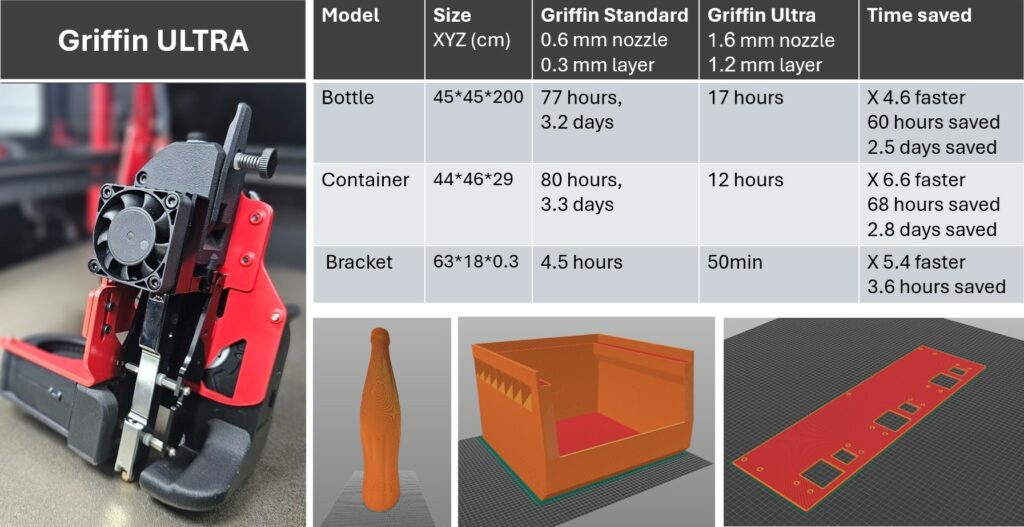

Griffin Ultra – Filament Extruder

The MAMA line of printers offers the versatility of printing with both pellets and filament. While pellet printing has its advantages, such as speed and cost efficiency, it can present challenges when detailed printing and high-resolution, smooth surfaces are required.

To address this, Modix MAMA printers come with the Griffin Ultra high-flow filament extruder as a default alternative. This print head can be easily installed in place of the Pulsar pellet extruder, allowing owners to enjoy the best of both worlds.

MAMA-XL3000 Specifications

- Print Volume: 3,000 x 1,000 x 1,000 mm (XYZ)

- Printer Dimensions: 2,030 x 3,760 x 2,422 mm

- Enclosure: Included

- Filament Print head (FFF) – Modix Griffin Ultra

- Flow Rate: 160 mm³/s, up to 500 gram/hour

- Nozzles: 1.6mm. Smaller nozzles are available as an add-on

- Sensors: filament runout and filament extruder clog detection

- (Future, currently not included) Pellet Print Head (FGF): Dyze Design Pulsar

- Flow Rate: 500 mm³/s, up to 3 KG/hour

- Nozzles: 3mm & 5mm. 1mm nozzle is available as an add-on

- Sensors: Pellets runout & pellet extrusion clog detection

- Material Compatibility (FGF&FFF): PLA, ABS, TPE, TPU, PVA, HIPS, PC, PETG, Nylon(PA), glass & carbon fiber filled, and recycled options

- Required: Air compressor (not included)

Required compressor specs: 3.5 HP, 24 liter/6.3 Gallon - Motion system: Closed loop nema23

- Electronic controller: Duet 6HC

- Optional Add-Ons: Air filter, additional nozzles, and more

- Future Add-Ons: IDEX with pellets or filament

- Reliability – The printer is equipped with clog and runout detection, allowing the printer to automatically pause and wait for operator to service the printer and continue the printing process.

- Delivery – Self assembly kit

Order & Lead Time

Join the experts who trust Modix and lead the future of 3D printing with the Modix MAMA-XL3000. The current production batch is scheduled for late 2025.

Shipping Considerations

- Our shipping is handled by couriers selected according to your location. Shipping terms: Incoterms 2020 DAP

- EU customers – If you’re an EU customer, please provide us with a valid VAT number. Without it, we’ll need to add an extra 21% VAT to your order

Request A Quote & Book a Personal Demo

You are welcome to contact our sales team at sales@modix3d.com or fill the form below to coordinate a video call and product tour. We will discuss your needs, show you the print and provide you with a detailed quote.