Case Study

Protecting Medical Teams with a 3D-printed Remote CT Scanner

The Company

Mr. R. Kulas, is an engineer at one of the world’s largest suppliers of healthcare technologies and diagnostic imaging. During the COVID-19 pandemic, he was tasked with designing and prototyping a remote control panel device for their popular CT scanners. This device would allow clinicians to do CT scans in safety and at a safe distance from potentially infected patients.

The Challenge

The challenge was that the control panels for CT scanners are typically located on the face of the scanner, putting clinicians at risk of exposure to the virus. Kulas used Modix to design a large remote control panel that could be 3D printed and used to control the scanner from a safe distance.

The Solution

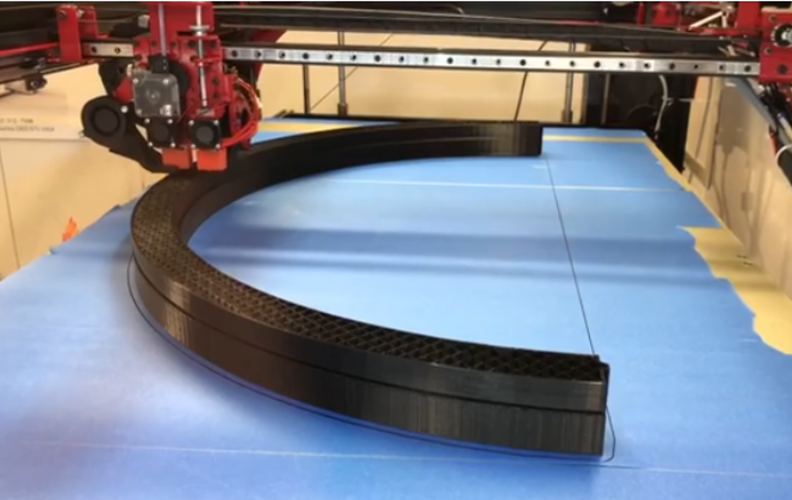

Kulas’s design for the remote control panel is being shared with the team so that they can go into production. The designed control panel is a large element of plastic equipped with sensors and LED lights that can instruct patients remotely to move according to the scanning procedure and needs. Hospitals are lining up for this device but some regulatory hurdles still need to be cleared before it can be approved for use.

Kulas is grateful for the opportunity to work on this project and to use his skills to help protect healthcare workers. He believes that using Modix 3D printing abilities is key to this project, as it allows the device to be printed quickly and easily in various locations around the world.

In addition to these benefits, 3D printing has also allowed Hicks to save a significant amount of money and time. This has allowed him to reinvest in his business and expand his offerings.

Overall, 3D printing has been a major boon for Hicks’s business. It has allowed him to create high-quality, custom furniture that is both affordable and sustainable. It has also allowed him to save time and money, which he can then reinvest in his business.

Tony3D.net is now able to offer its customers a wider range of 3D models, including large-format models, complex models, and models with a high level of detail. The company has also been able to reduce turnaround times and improve its customer satisfaction.

If you are a 3D printing company that is looking to create large-format models, the Modix BIG-60 is a great option.

Information box:

Creator: Mr R. Kulas, Engineer, for Diagnostic Imaging

Application: Medical devices and implants

Telemedicine and remote healthcare

Production of final goods

Vertical: Med-Tech

Printers: Modix BIG-120X