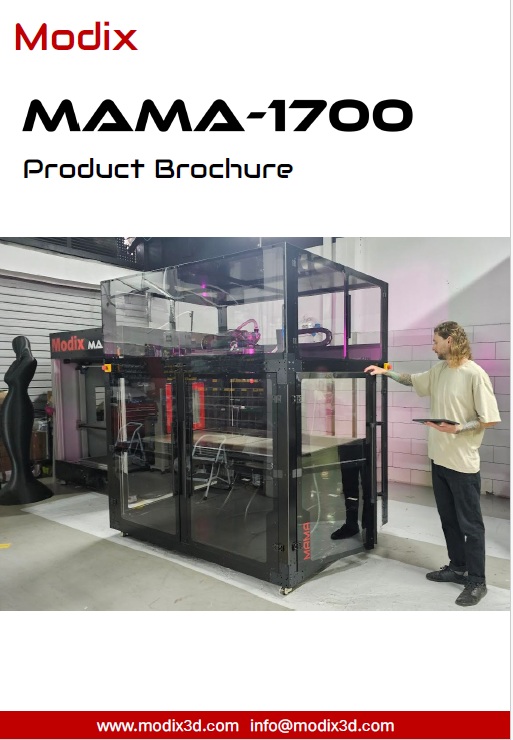

MAMA-1700 Pellet 3D Printer

Built for Production & Accelerated R&D

The MAMA-1700 is Modix’s flagship FGF (Fused Granulate Fabrication) 3D printer, engineered to print primarily with plastic granulates instead of filament. This lowers material costs to just a few dollars per kilogram and opens access to a wider range of polymers, from high-performance industrial compounds to sustainable recycled options.

For added versatility, the MAMA-1700 also comes with Modix’s Griffin Ultra filament print head, capable of printing up to 0.5 kg per hour for detailed parts. This dual configuration allows owners to enjoy the benefits of both technologies, filament and pellets.

With its large build volume of 1,700 X 1,000 X 1,000 mm and high-throughput extrusion, the MAMA-1700 is purpose-built for fast R&D iterations and production-grade parts. Projects that once required days can now be completed in hours.

Faster Return on Investment

For manufacturers, design studios, and innovators, the MAMA-1700 delivers a clear ROI by cutting both time-to-part and material expenses—thanks to pellet costs of just a few dollars per kilogram—making it a powerful platform for scaling ideas from concept to production.

Install Anywhere

The printer is offered as a self-assembly kit, allowing installation in almost any location — even rooms with narrow doors or basement workshops where fully assembled machines wouldn’t fit.

Material Freedom

Using plastic granules unlocks virtually unlimited material options, far beyond what filament can offer. Custom polymer blends, recycled plastics, and functional additives can be developed and tested directly in production—delivering faster innovation and greater flexibility for researchers and businesses alike.

Unlock Exclusive Modix Resources – Get Your Free Downloads!

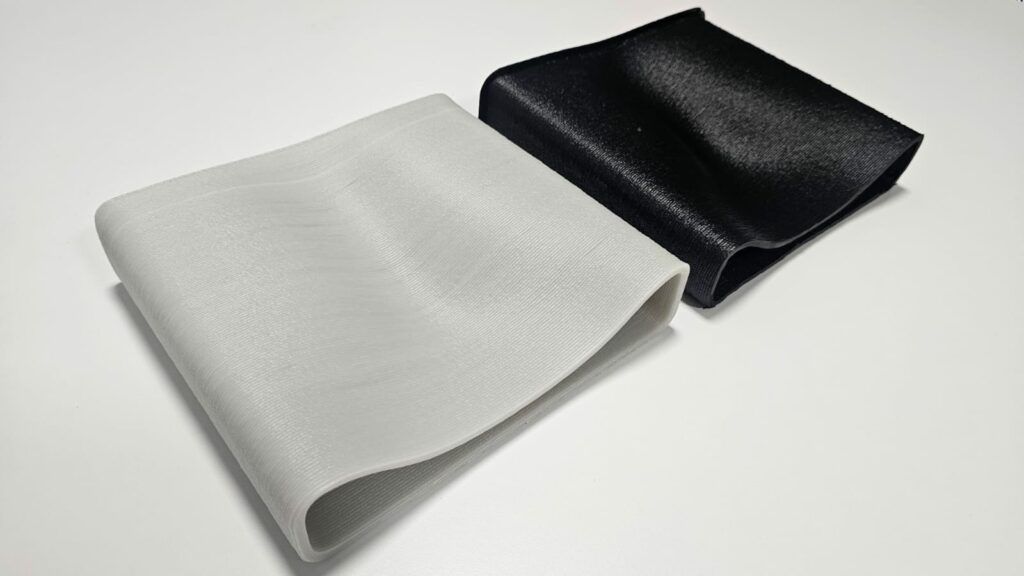

Samples

Mold

Low temperature Mold made of wood filled pellet. Wood filler makes it very easy for post processing including sanding, drilling etc.

- Length: 1.4 Meter, Weight 7 kg

- Print time 5 hours

- nozzle – 3mm, extrusion width – 4mm

- layer height – 2mm

- Wood PLA

Composite Materials

Printing with composite pellets, such as PETG CF (Carbon Fiber) and PETG GF (Glass Fiber), results in strong, rigid parts that can withstand high impact and stress. These materials not only enhance the mechanical properties of the printed parts but also improve overall printability. The added fibers reduce material shrinkage during cooling, minimizing warping. Carbon fibers, in particular, offer superior heat dissipation, allowing for shorter layer times and enabling faster printing, especially for smaller objects.

- 22 cm X 23 cm X 5cm

- Print time ~1 hours

- nozzle – 3mm

- layer height – 1.5mm

- PETG CF (Black) PETG GF (Gray)

Furniture & Decor

Signage

MAMA-1700 Specifications

- Print Volume: 1.7 x 1.0 x 1.0 meters (XYZ)

- Printer Dimensions: 2.1 x 1.53 x 2.35 meters (XYZ)

- Enclosure: Included

- Pellet Print Head (FGF): Dyze Design Pulsar

- Flow Rate: 500 mm³/s, up to 3 KG/hour

- Nozzles: 3mm & 5mm. 1mm nozzle is available as an add-on

- Sensors: Pellets runout & pellet extrusion clog detection

- Filament Print head (FFF) – Modix Griffin Ultra

- Flow Rate: 160 mm³/s, up to 500 gram/hour

- Nozzles: 1.6mm. Smaller nozzles are available as an add-on

- Sensors: filament runout and filament extruder clog detection

- Material Compatibility (FGF&FFF): PLA, ABS, TPE, TPU, PVA, HIPS, PC, PETG, Nylon(PA), glass & carbon fiber filled, and recycled options

- Required: Air compressor (not included)

Required compressor specs: 3.5 HP, 24 liter/6.3 Gallon - Motion system: Closed loop nema23

- Electronic controller: Duet 6HC

- Optional Add-Ons: Air filter, additional nozzles, and more

- Future Add-Ons: IDEX with pellets or filament

- Reliability – The printer is equipped with pellet extruder clog and pellets supply runout detection, allowing the printer to automatically pause and wait for operator to service the printer and continue the printing process.

- Delivery – Self assembly kit or pre-assembled by our certified partners.

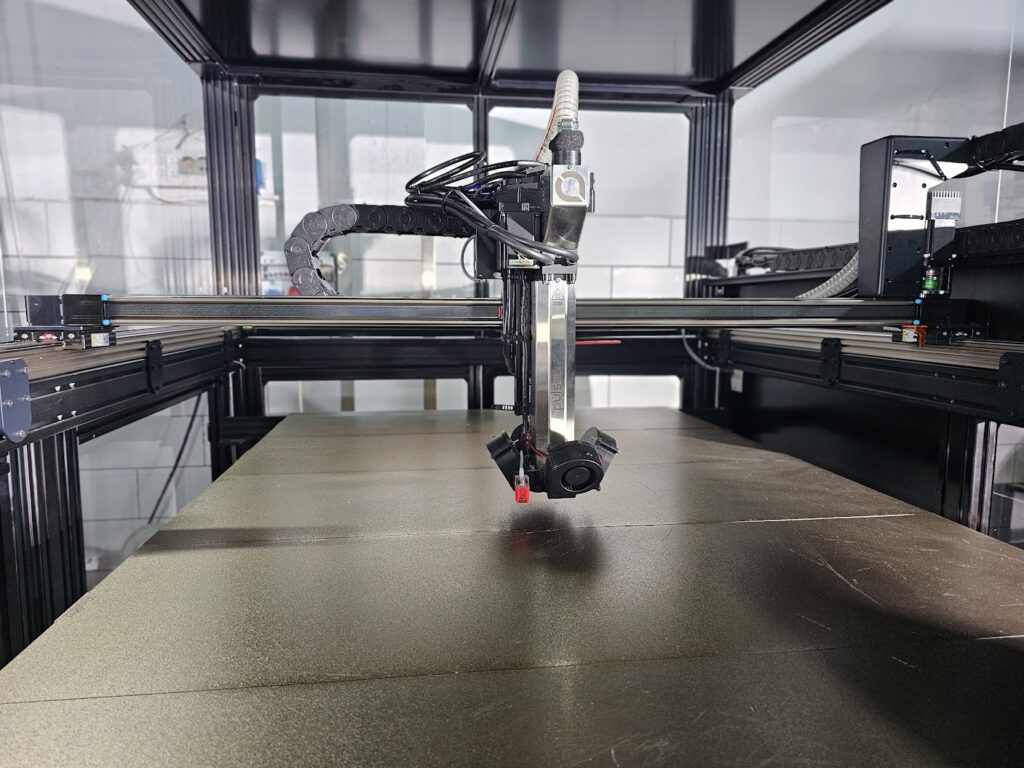

MAMA-1700 Pellet Extruder

Key Features:

- High Flow Rate: Capable of delivering a flow rate of up to 500 mm³/s, enabling the printing of large-scale objects at speeds of up to 3 kilograms per hour.Material Versatility: Supports a wide range of materials including PLA, ABS, TPE, TPU, PVA, HIPS, PC, PETG, Nylon, and composites such as wood, glass fiber, and carbon fiber filled. It also accommodates recycled materials, enhancing sustainability.

- Precision and Reliability: Built with precision engineering to ensure consistent and reliable extrusion, crucial for industrial applications.

- Ease of Maintenance: Designed for easy maintenance, reducing downtime and operational costs.

- Nozzle and Screw selection – Dyze Pulsar offers nozzles from 1mm to 5mm diameter and several screws to meet your pellet 3d printing needs.

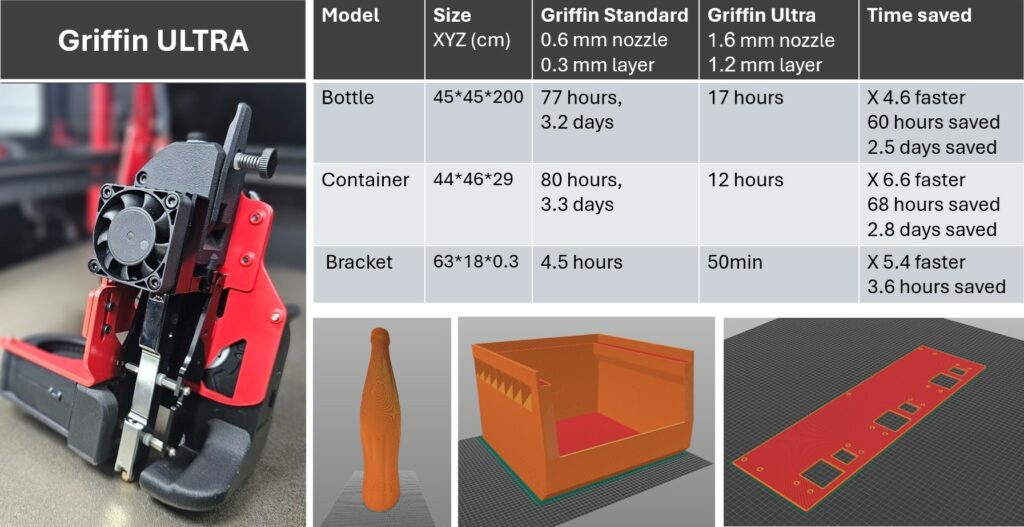

Griffin Ultra – Filament Extruder

The MAMA line of printers offers the versatility of printing with both pellets and filament. While pellet printing has its advantages, such as speed and cost efficiency, it can present challenges when detailed printing and high-resolution, smooth surfaces are required.

To address this, Modix MAMA printers come with the Griffin Ultra high-flow filament extruder as a default alternative. This print head can be easily installed in place of the Pulsar pellet extruder, allowing owners to enjoy the best of both worlds.

IDEX and Dual-Material Printing

The MAMA line of printers will also supports IDEX (Independent Dual Extruder) technology, enabling dual-material printing. With the option to use a secondary print head, users can print with a combination of pellet and pellet or pellet with filament. This setup is particularly advantageous for support structures, as water-soluble filament can be used for easy post-processing and support removal, which is challenging with pellet prints. This capability allows for the creation of complex internal geometries and cavities, enhancing design flexibility and reducing the time and effort required for post-processing. ETA for the IDEX add-on – Q1/2025

Order & Lead Time

Join the experts who trust Modix and lead the future of 3D printing with the Modix MAMA-1700.

MAMA printers are made in batch productions and new printers are coming out every 8 weeks time.

Contact sales team for an updated lead time and stock availability.

Shipping Considerations

- Our shipping is handled by couriers according to your location. Shipping terms: Incoterms 2020 DAP.

- US customers are subjected to 12% import duties.

- EU customers – Please provide us with a valid VAT number.

Request A Quote & Book a Personal Demo

You are welcome to contact our sales team at sales@modix3d.com or fill the form below to coordinate a video call and product tour. We will discuss your needs, show you the print and provide you with a detailed quote.